Defect Detection & Quality Inspection

The use of computer vision for defect detection and quality assurance offers several significant advantages over traditional manual inspection methods. Firstly, it eliminates human subjectivity and fatigue, ensuring consistent and objective assessment of product quality. Secondly, it significantly enhances the inspection speed and throughput, enabling faster and more efficient production cycles. Lastly, it improves overall product quality by minimizing the risk of undetected defects or errors.

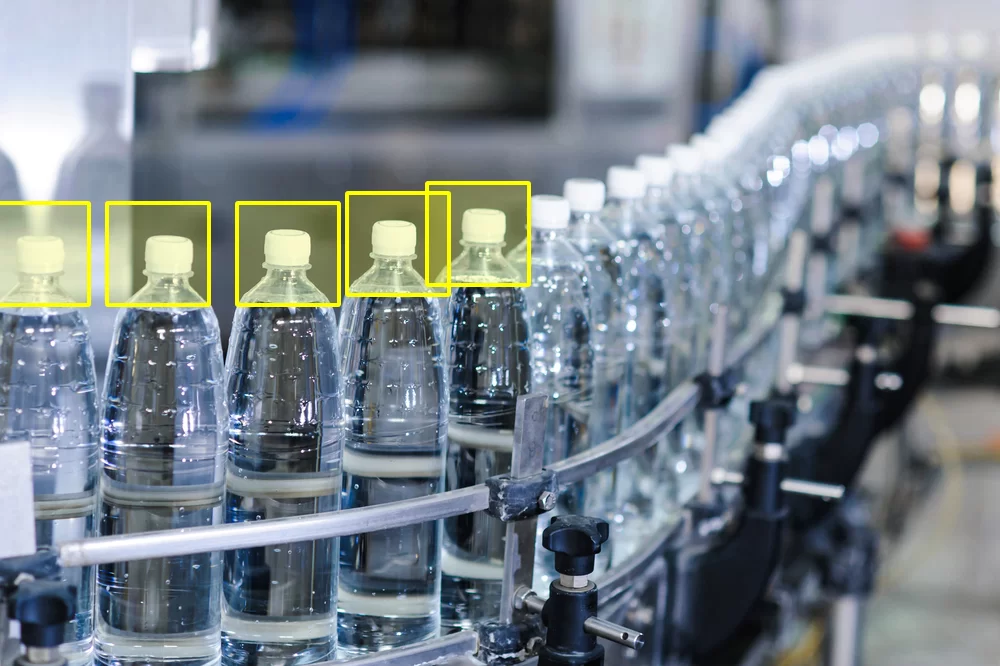

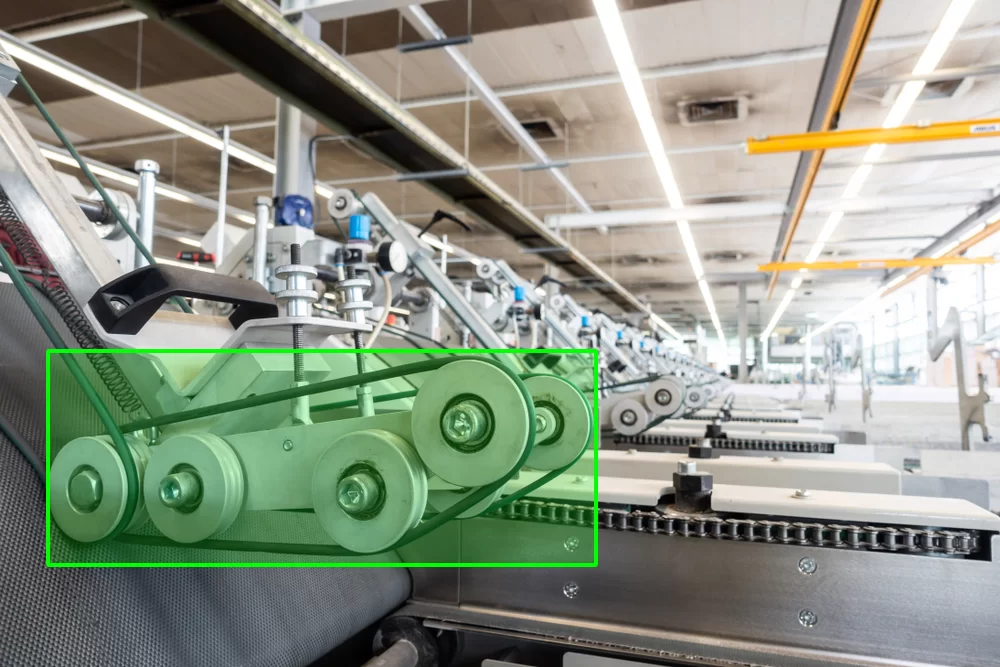

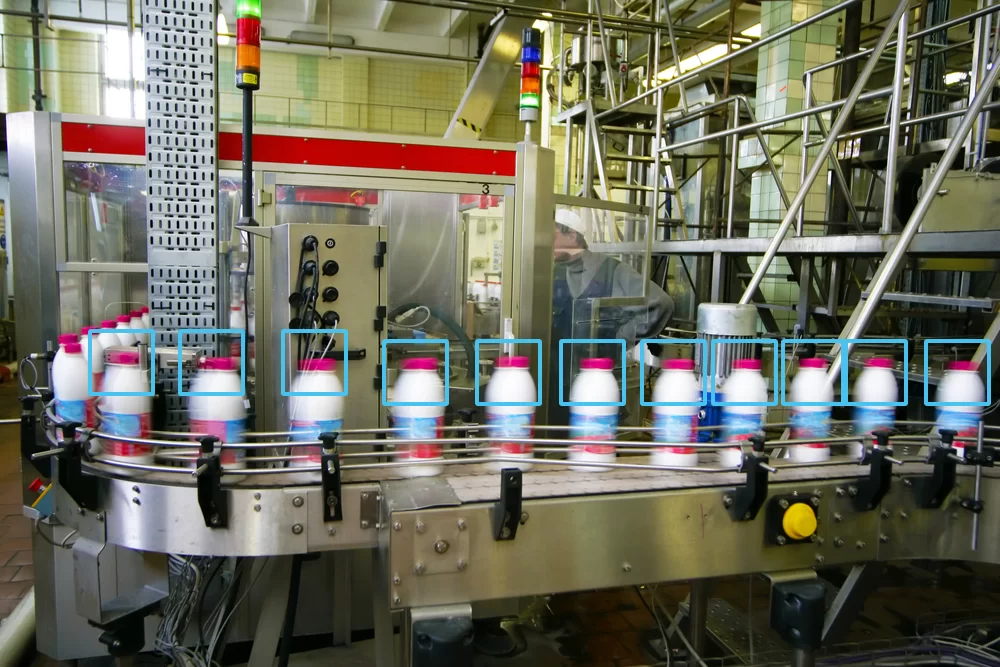

Real-time monitoring is another critical aspect of computer vision-based quality assurance. By continuously analyzing live video feeds or images from the production line, computer vision systems can identify anomalies and deviations from the expected quality standards. This enables immediate intervention and corrective actions, minimizing the impact of defective products on downstream processes and customer satisfaction.

Create an alternative solution based on computer vision

Our device can be placed strategically in key locations across your sites. Whilst in operations.

SparkIntelligence has created an alternative solution based on computer vision and deep learning technology. Our solution reduces the need for human workers to visually inspect and monitor manufacturing and production processes leading to fewer errors, streamlined workflows and cost-saving initiatives. Some regulations require manual inspections – but human fatigue and staff training can affect accuracy and scalability.

The integration of computer vision into quality assurance workflows not only improves defect detection but also provides valuable insights for process optimization.

Product Overview

Our solution can effectively detects defects of interests or monitor your production processes for quality assurance purposes using your existing infrastructure or our proprietary device ensuring product quality and minimizing defects in manufacturing processes

Computer vision systems can detect various types of defects, such as surface imperfections, dimensional irregularities, color variations, shape deviations, and faulty components. The algorithms can also perform complex inspections, including verifying proper labeling, checking for correct assembly, and detecting foreign objects or contaminants.

Product Benefits

Increase staff productivity

Improve product quality

Improve accuracy and reduce waste