ForkVision

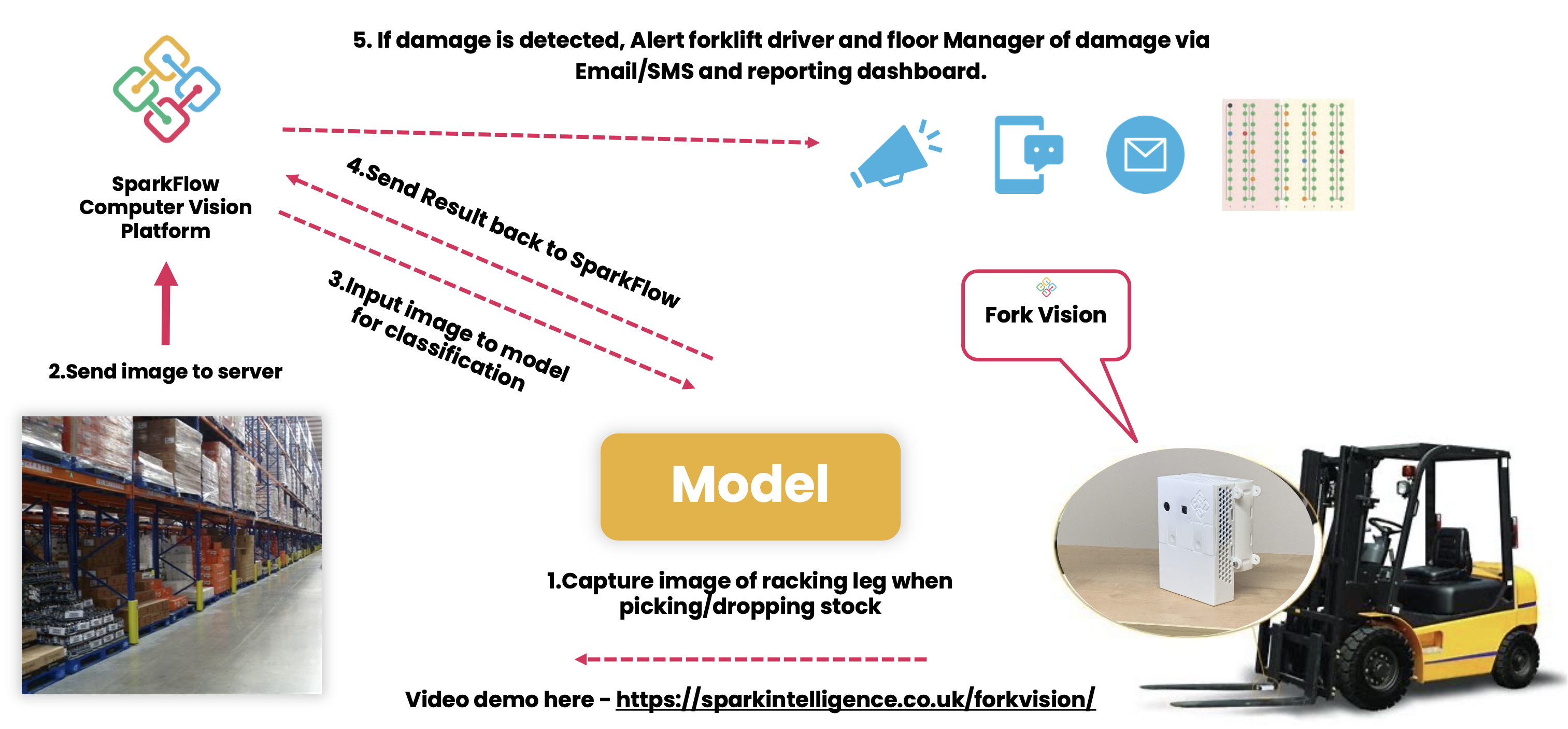

Rack impacts can go unnoticed for dangerously long periods of time increasing the risk of racks collapsing, leading to operational downtime, escalating maintenance costs and in more severe cases loss of lives. Forkvision addresses this problem through the deployment of a state-of-the-art computer vision algorithm based solution, strategically monitoring the health of racking through operational Forklifts, feeding data into an analytics dashboard and notifying the management team of detected damage in a timely manner.

Real-time Pallet Racking Defect Detection

Our solution provides real-time notifications to the forklift driver and site management on detection of a defect.

In a larger warehouse or distribution centre with numerous racking legs, monitoring the status of every single racking leg can become a tedious, time consuming and near-impossible task to be carried out manually. However, if racking damages are not detected and addressed in a timely manner, this can lead to catastrophe, reputational damages and in some cases, potential loss of life.

The existing solution in the market requires placing a sensor on every racking leg to monitor and report any impact caused by forklifts. However, this solution creates undue complexity and increases hardware acquisition and maintenance cost due to the large-scale deployment of sensor devices.

Product Overview

Our first offering, “ForkVision” solves this problem through a state-of-the-art computer vision algorithm embedded device strategically mounted on a forklift as opposed to each racking leg. This effectively adds intelligent and mobile eyes to the forklift instead of a static sensor on each rack, thereby increasing safety, reducing costs and boosting efficiency.

Based on the principles of deep and active learning, the embedded algorithm is able to continuously learn and adapt to changes in its environment thereby improving the accuracy of its prediction.

Product Benefits

Magnetic mounting to forklifts

Industrial enclosure

Continuous Model optimisation through ‘Active-Learning’.

Model trained on Real dataset containing thousands of racking legs.

Environment-specific Model adaption, providing a highly custom solution for every Warehouse.

Analytics dashboard detailing damage types, clusters and more.

Rechargeable device